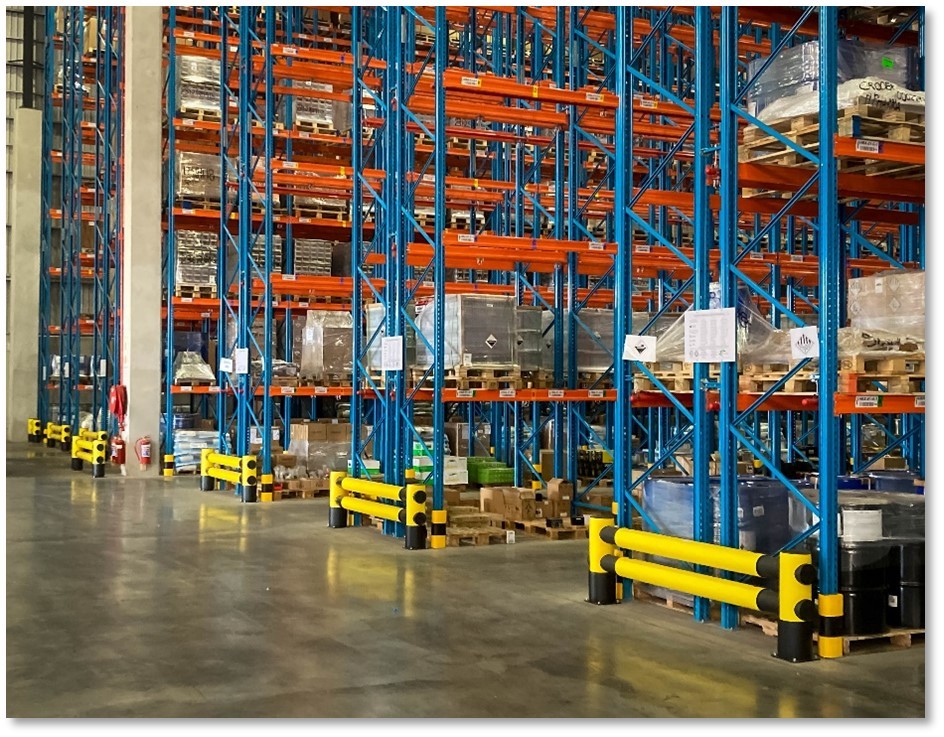

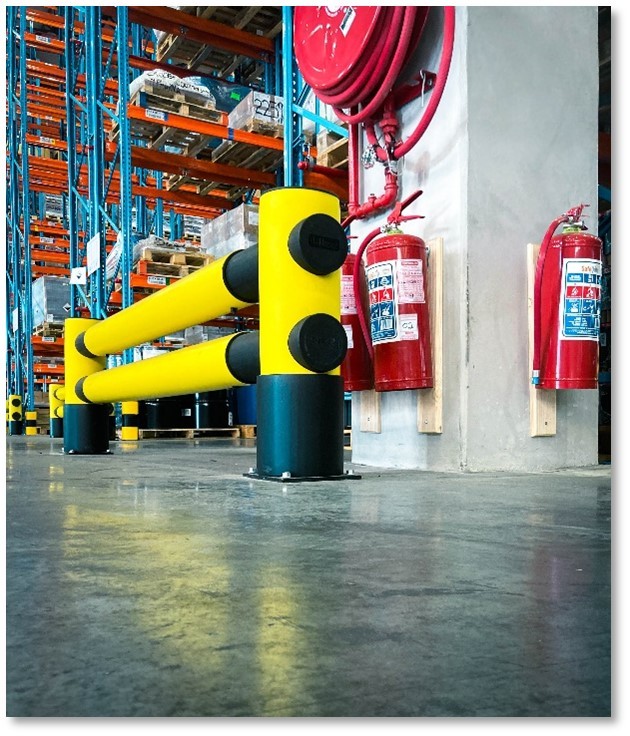

PROMHS was recently requested to design and offer a barrier solution for a client’s flammable warehouse in Jet Park, South Africa. Preference was given to Polymetric Barriers which has a lesser ignition potential in relation to the typical industry steel barriers. PROMHS approached their distributor d-flexx whom offer one of the best engineered safety barriers that are designed not to increase the risk of fire or fire spreading at the place of use.

UNDERSTANDING MATERIAL PROPERTIES:

When it comes to assessing fire hazards in polymer barriers, the choice of materials is critical. Some manufacturers opt for cheaper and potentially more dangerous materials, which can significantly increase the risk during a fire. The table below compares key properties of d-flexx PE, PVC, and PP materials to highlight why careful selection is essential.

IGINITION TEMPERATURE:

The ignition temperature of a material indicates the amount of thermal energy needed to start a fire. d-flexx PE barriers have an ignition temperature of 350°C, higher than flexible PVC and wooden pallets. This means that in the event of a fire, d-flexx barriers will likely be among the last to ignite, reducing their role as fire accelerants.

THERMAL DECOMPOSITION TEMPERATURE:

Thermal decomposition temperature is the point at which a material begins to chemically break down and lose its shape. PE polymer remains stable up to 340°C, whereas PVC starts decomposing at 249-273°C. In practical terms, materials with lower decomposition temperatures, like PVC, will fail sooner in a fire compared to more fire-resistant materials like PE.

SMOKE AND TOXIC FUMES:

Smoke development in a fire poses a significant danger to humans and animals, often more so than the flames. Many polymer barriers emit toxic smoke; PVC, for example, releases harmful hydrogen chloride. In contrast, PE materials, such as those used in d-flexx barriers, do not emit environmentally hazardous gases during combustion, making them a safer choice.

HORIZONTAL FLAME RETARDATION

According to the UL94 fire classification, a material with a thickness of 3mm to 13mm should decompose by fire at a rate no greater than 40mm per minute. The PE polymer used in d-flexx barriers meets this standard, classified as UL94HB, confirming its effective flame retardation capabilities.

BENEFITS of d-flexx

– One for all temperature ranges -40 to 50°C

– Saver choice during combustion (no hazardous gases)

– Decomposition temperature 340 – 350°C

– Flash point (ignition) 350-360° C

#PROMHS #SafetyBarriers #WarehouseSafety #FacilitySafety #FacilityMaintenance #WarehouseMaintenance #SafetyProducts #IndustrialSafety #WorkplaceSafety #SafetySolutions #PolymericBarriers #SafetyEquipment #SafetyInnovation #CaseStudies #WorkplaceProtection #PolymericGuardrails #PolymericSafetyBarriers #dflexx